Have you ever noticed tiny cracks forming on the surface of your favorite items, like ceramics, glass, or even some plastics? This phenomenon is called crazing, and it can be both fascinating and frustrating.

Understanding crazing is key to protecting your belongings and knowing when something might be at risk. You’ll discover what crazing really is, why it happens, and how you can spot it before it causes bigger problems. Keep reading to learn how to keep your items looking their best and avoid costly damage.

What Is Crazing

Crazing is a common issue you might encounter with plastics, ceramics, or coated surfaces. It appears as a network of fine cracks that don’t go all the way through the material but can weaken it over time. Understanding what causes crazing and how to spot it early can save you from costly repairs or replacements.

What Does Crazing Look Like?

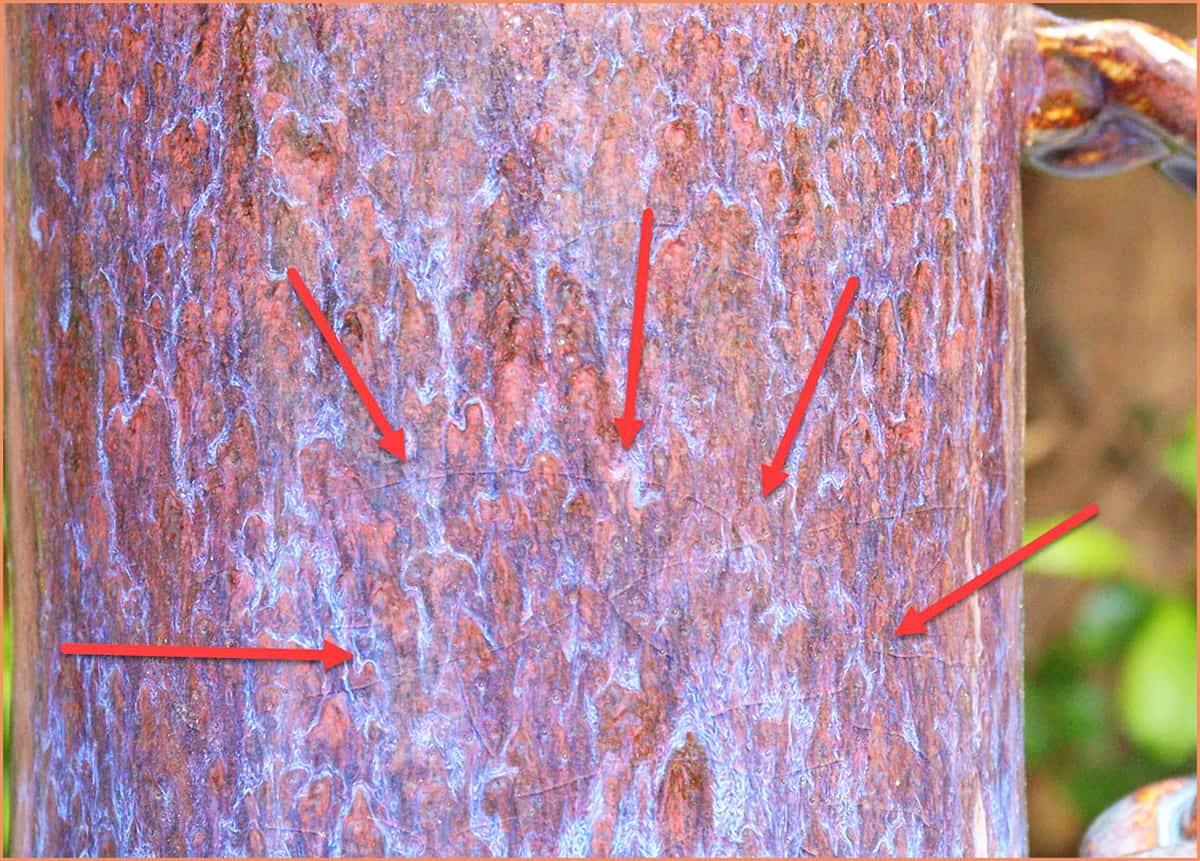

Crazing shows up as tiny, interconnected cracks that form a web-like pattern. You might notice it on clear plastic items, like eyeglass lenses or containers, where it looks like spiderweb cracks. It doesn’t break the surface completely but creates a fragile texture that worsens with stress.

Why Does Crazing Happen?

Crazing occurs when the material undergoes stress beyond its ability to stretch, often from temperature changes or chemical exposure. Imagine bending a plastic ruler back and forth—it eventually shows small cracks on the surface before it snaps. These micro-cracks form because the material’s surface and inner layers react differently to pressure or environmental factors.

How Can You Prevent Crazing?

- Avoid exposing materials to sudden temperature changes.

- Use compatible cleaning agents that don’t weaken the surface.

- Store items away from harsh sunlight or chemicals.

Have you ever wondered if the cleaning spray you use on your plastic gadgets might cause damage over time? Choosing the right products can make a big difference in preventing crazing.

Is Crazing Dangerous?

Though crazing doesn’t cause immediate breaks, it signals weakening. Over time, those fine cracks can grow and lead to material failure. If you see crazing on safety equipment, like helmets or safety goggles, it’s best to replace them to avoid risks.

Common Causes

Crazing is a common problem in many materials, especially plastics and ceramics. It appears as a network of fine cracks on the surface. Understanding what causes crazing helps prevent damage and extends the life of products. Several key factors contribute to this issue.

Material Stress

Stress on materials often triggers crazing. It happens when the material undergoes excessive force or pressure. This stress can be internal, like uneven cooling during production. External forces, such as bending or impact, also cause tiny cracks to form. Over time, these cracks spread and create a web-like pattern.

Environmental Factors

Environmental conditions play a big role in crazing. Exposure to sunlight and heat can weaken materials. Chemicals, like cleaning agents or solvents, attack the surface and cause cracks. Moisture absorption may lead to swelling and surface tension, which encourages crazing. Frequent temperature changes cause expansion and contraction, increasing the risk.

Manufacturing Defects

Defects during production often lead to crazing later. Poor mixing of raw materials creates weak spots. Incomplete curing or drying leaves the surface vulnerable. Contamination by dust or oil causes uneven surfaces. Incorrect processing temperatures can induce stress inside the material. These defects make it easier for cracks to develop under normal use.

Identifying Crazing Early

Identifying crazing early helps prevent further damage and costly repairs. Small cracks on surfaces can grow over time. Catching these signs quickly allows timely action. This section explains how to spot crazing by observing changes in appearance and texture.

Visual Signs

Crazing appears as tiny, fine cracks on the surface. They often look like spiderweb patterns or a network of lines. These cracks may be white or slightly lighter than the base color. Check areas exposed to heat, chemicals, or stress first. Early crazing may be hard to see without close inspection. Use good lighting and a magnifying glass if needed.

Surface Texture Changes

Surface texture may feel rougher or uneven where crazing occurs. Run your fingers gently over the area to detect irregularities. The surface might lose its smooth or glossy finish. These texture changes often happen before visible cracks appear. Touch helps identify subtle damage that eyes might miss. Detecting texture shifts early signals the start of crazing development.

Credit: potterycrafters.com

Prevention Techniques

Preventing crazing helps keep materials strong and looking good. Understanding how to stop crazing can save time and money. Use smart techniques to reduce the chance of tiny cracks forming. Focus on the right materials, environment, and upkeep.

Proper Material Selection

Choose materials that resist crazing under stress. Look for plastics and coatings designed to handle heat and chemicals well. Avoid brittle materials that crack easily. Use additives that improve flexibility and durability. Test materials before full use to ensure they meet needs.

Controlled Environment

Keep temperature and humidity stable around sensitive materials. Avoid rapid changes in heat or cold that cause stress. Protect surfaces from harsh chemicals or UV light that weaken them. Use covers or barriers to shield materials from damaging elements. Maintain clean areas to prevent dirt build-up that worsens crazing.

Regular Maintenance

Inspect materials often for early signs of crazing. Clean surfaces gently to avoid adding stress. Repair small cracks quickly before they grow. Replace worn parts to keep structures strong. Schedule routine checks to catch problems early and extend material life.

Repair Methods

Repairing crazing requires careful steps to restore the surface and prevent further damage. Proper repair methods improve the appearance and extend the life of the material. Each step plays a vital role in fixing cracks and achieving a smooth finish.

Cleaning And Preparation

Start by cleaning the affected area thoroughly. Remove dirt, grease, and loose particles with a mild detergent and water. Use a soft brush or cloth to avoid scratching the surface. Dry the area completely before moving forward. Proper preparation ensures better adhesion of repair materials.

Filling And Sealing Cracks

Use a suitable filler designed for the surface type. Apply the filler gently into the cracks using a putty knife or applicator. Press firmly to fill all gaps and avoid air pockets. Allow the filler to dry fully according to the product instructions. After drying, sand the area lightly to create a smooth, even surface ready for finishing.

Polishing And Finishing

Polish the repaired section to blend it with the rest of the surface. Use fine-grit sandpaper or polishing compounds for best results. Buff the area with a soft cloth to restore shine and smoothness. Finishing touches improve the look and protect the repair from future crazing.

Credit: potterycrafters.com

Expert Tips For Lasting Repairs

Fixing crazing requires careful work and the right approach. Lasting repairs depend on the materials used and how the repair is done. Avoiding errors can save time and keep surfaces strong. Knowing when to call experts can prevent bigger problems.

Using Quality Materials

Good materials make repairs stronger and longer lasting. Choose fillers and coatings designed for your surface type. Cheap products may crack or peel quickly. Test small areas before full application. Proper drying and curing times improve durability.

Avoiding Common Mistakes

- Do not ignore surface preparation. Clean and dry well before repair.

- Avoid applying too thick layers. Thin coats work better and dry faster.

- Prevent mixing incompatible products. Check labels for compatibility.

- Do not rush the process. Allow proper curing time between steps.

When To Seek Professional Help

Some damage needs expert tools and skills. Large or deep crazing may worsen if fixed wrongly. Professionals can assess structural issues beneath the surface. Consult them if repairs fail or damage spreads. Investing in expert repair can save money later.

Case Studies

Cracking and crazing might seem like minor imperfections, but they can have significant implications in various contexts. By examining real-world case studies, we can uncover practical lessons on how to manage and mitigate these issues. Whether you’re a homeowner or someone working in an industrial setting, these insights can guide you in making informed decisions.

Home Repairs

Imagine you’re fixing up an old house. You notice tiny cracks on your walls—crazing. It might look like a daunting task, but addressing it can be surprisingly manageable. Start by cleaning the affected area thoroughly.

Apply a quality sealant specifically designed for your wall type. This not only improves the aesthetic but also prevents further deterioration. Don’t ignore the importance of a smooth finish; it can be the difference between a quick fix and long-term peace of mind.

Have you ever wondered how these small cracks can affect your home’s value? Potential buyers often see them as signs of neglect. Addressing crazing can enhance your property’s appeal and ensure a better return on investment.

Industrial Applications

In industrial settings, crazing can impact the integrity of materials. It’s not just a cosmetic concern; it can lead to equipment failure. Regular inspections can help detect crazing early. Consider implementing routine checks as part of your maintenance strategy.

Using advanced materials that are resistant to crazing is another effective approach. It might require an upfront investment but can save you from costly repairs and downtime. Examine your current materials and identify areas where improvements are necessary.

If crazing is already present, consult with industry experts. Their insights can provide tailored solutions that fit your specific needs. Are you willing to invest in preventative measures to ensure operational efficiency? The choice could define your success.

Credit: www.reddit.com

Frequently Asked Questions

What Causes Crazing In Materials?

Crazing occurs due to stress, environmental factors, or aging. It forms tiny cracks on surfaces, weakening the material over time. Common causes include UV exposure, chemical reactions, and mechanical stress.

How Can Crazing Be Prevented Effectively?

Prevent crazing by reducing stress and exposure to harsh chemicals. Use protective coatings and UV stabilizers to shield materials. Proper storage and handling also minimize crazing risks.

Is Crazing Harmful To Plastic Products?

Yes, crazing weakens plastic, reducing durability and aesthetic appeal. It can lead to fractures or failure under stress. Early detection helps prevent further damage.

Can Crazing Be Repaired Or Reversed?

Minor crazing can be polished or treated with solvents. Severe crazing often requires replacement of the material. Repair options depend on the material type and extent of damage.

Conclusion

Crazing shows tiny cracks on surfaces like glass or plastic. It often appears due to stress or aging. These cracks can weaken the material over time. Detecting crazing early helps prevent bigger problems later. Regular checks keep items safer and longer-lasting.

Simple care can reduce crazing’s impact. Understanding crazing helps in making smart repairs. Keep an eye on any small cracks you see. This way, you protect your belongings and avoid costly fixes. Crazing may seem small, but it deserves attention.